Marble stripping

Keywords:

Category:

- Description

-

- Commodity name: Marble stripping

The release performance of Anhua Biological Technology PVA degradable film will reduce the burrs and other components produced after the release, greatly reducing the grinding time.PVA (polyvinyl alcohol) film-The film used for the release of artificial marble has excellent softness and smoothness, which is smoother when the mold is released and the mold is released.PVA (polyvinyl alcohol) film-The heat resistance of the film for the release of artificial marble can reach up to 190℃.

The release performance of Anhua Biological Technology PVA degradable film will reduce the burrs and other components produced after the release, greatly reducing the grinding time.PVA (polyvinyl alcohol) film-The film used for the release of artificial marble has excellent softness and smoothness, which is smoother when the mold is released and the mold is released.PVA (polyvinyl alcohol) film-The heat resistance of the film for the release of artificial marble can reach up to 190℃.

Anhua Biotechnology is a manufacturer of PVA degradable water-soluble film substrates.Under the same thickness and temperature, Anhua Biological Technology's water-soluble film dissolves quickly and has no residue.The raw material brand uses Japanese Kuraray/domestic Chuanwei, controls the quality from the source, and is equipped with high-precision core equipment from Japan and the United States. It has high uniformity, good weather resistance, and is less affected by climate. , More stable performance.

Specification: Thickness 25µm-60µm

The length of each roll is 200 yards, or customized according to customer needs

Width: 1000㎜-1800㎜

The company's core technology is environmentally friendly technology. The raw material of the biodegradable film, polyvinyl alcohol, does not undergo any treatment in the natural environment. The final degradable substances are carbon dioxide and water. The product function is better than that of traditional plastic special functional films, with environmental protection, high strength and wear resistance, mold release, oxygen barrier, anti-static, oil resistance and solvent resistance.

Qualification

Xinzhou City Innovative Small and Medium-sized Enterprises

Xinzhou City Innovative Small and Medium-sized Enterprises

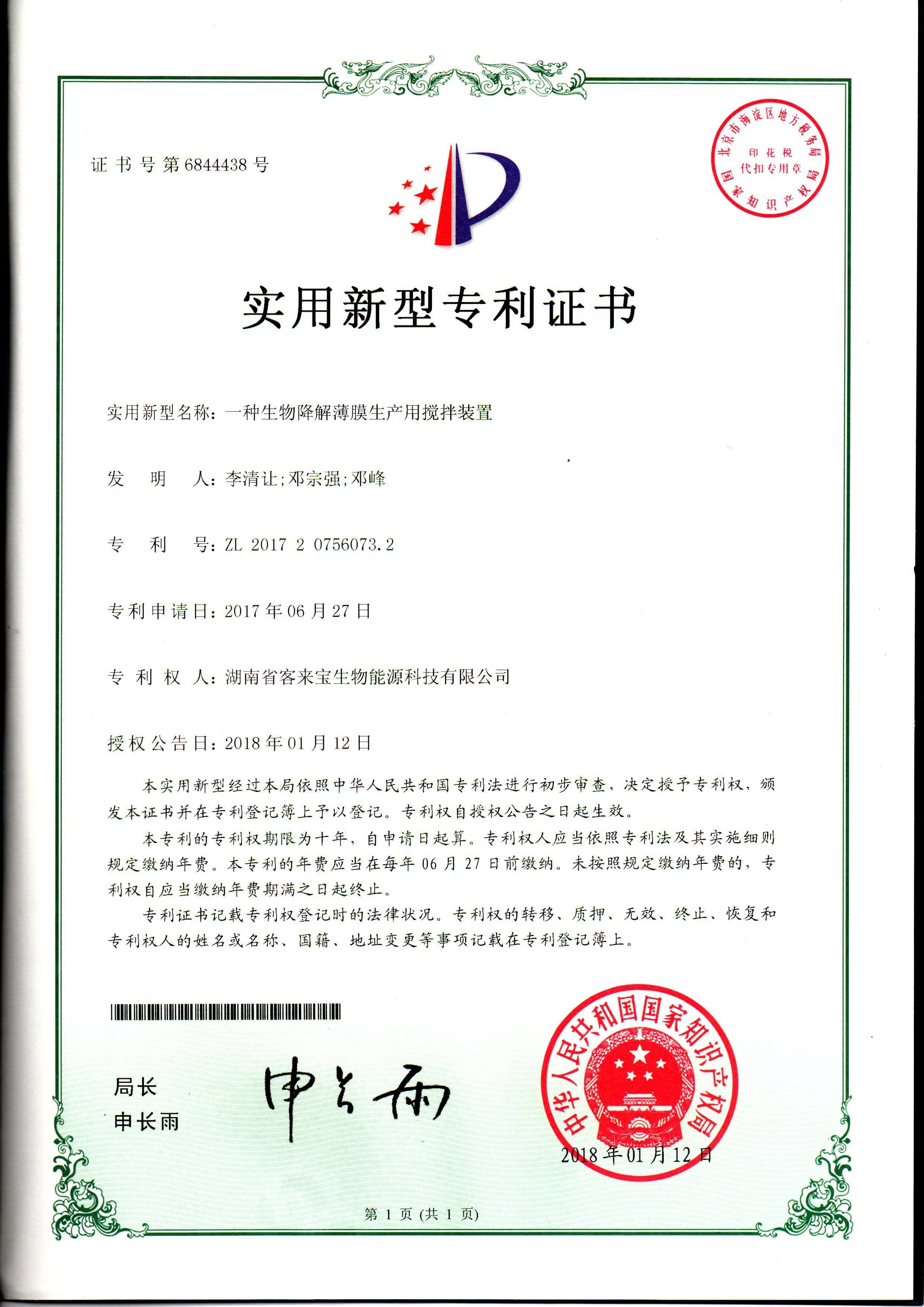

A stirring device for the production of biodegradable film

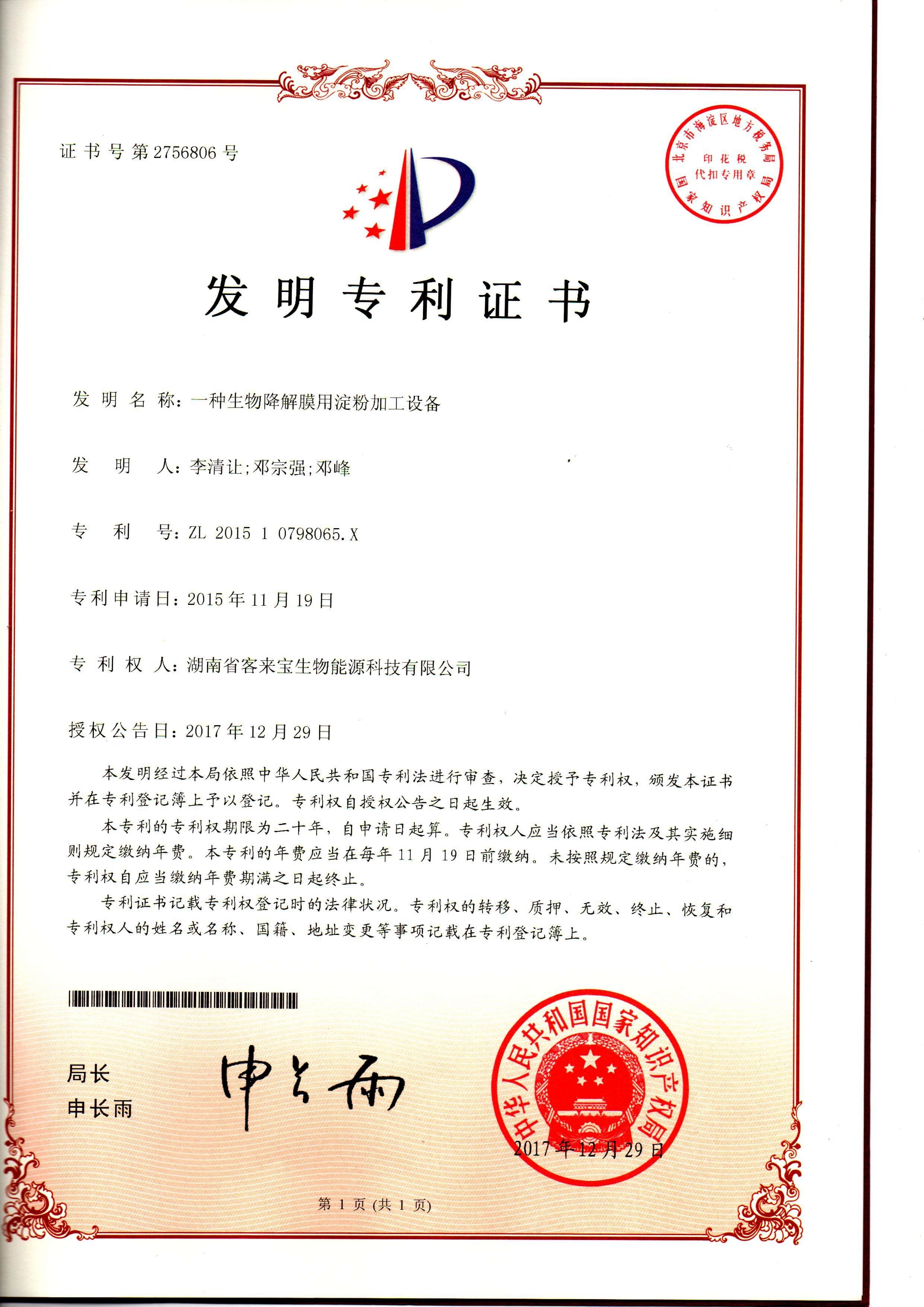

Starch processing equipment for biodegradable film

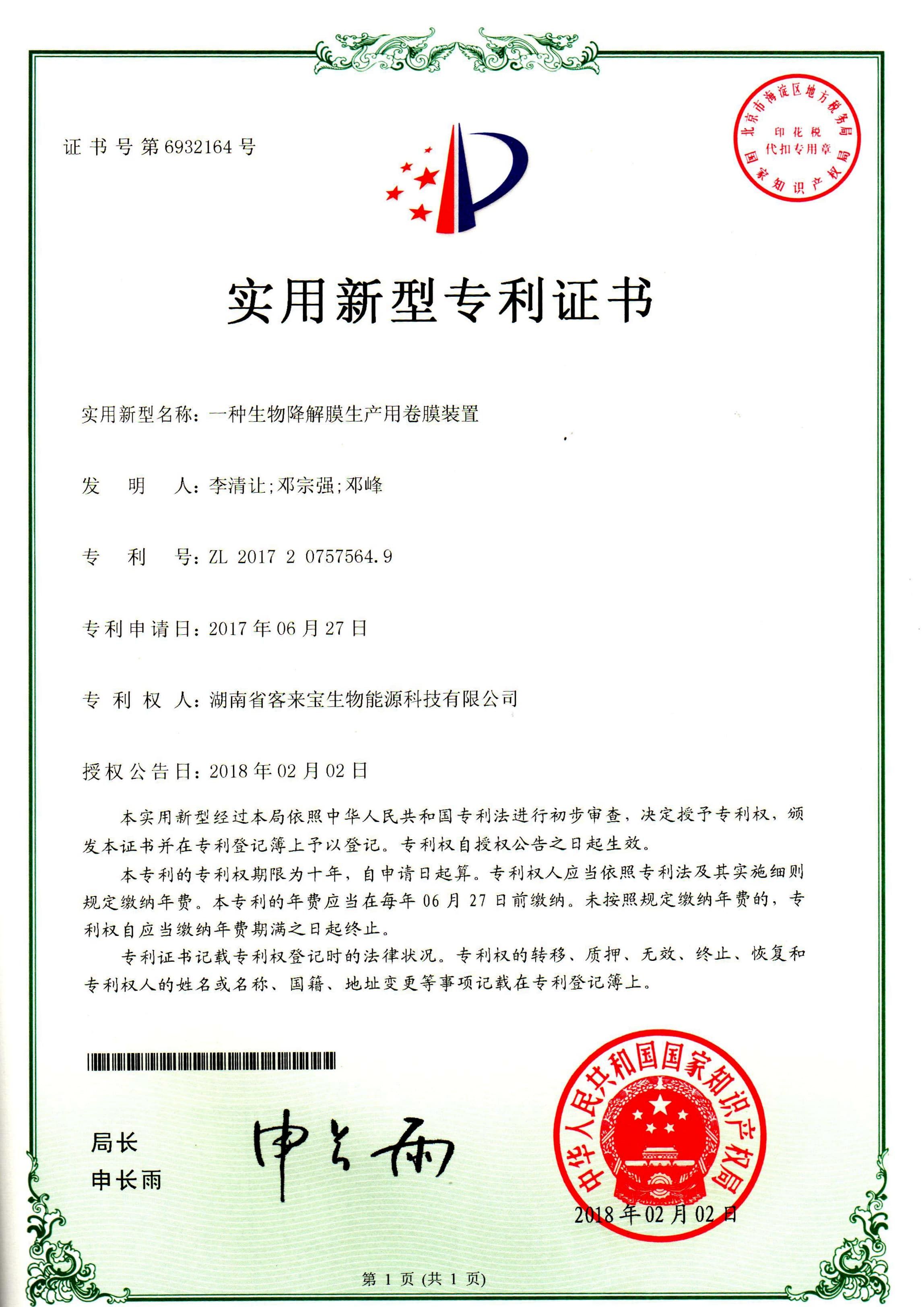

A film rolling device for the production of biodegradable film

Previous:

Next:

Product inquiry

Related products